Steel Shelving

For decades, Steel Shelving has been the standard for inventory and parts storage within the warehousing industry. Their clean appearance and excellent load capacities make it the primary choice within light duty applications for automotive, aviation, and other highly regulated industries. All materials are given a rust-resistant treatment before the powder-coat finish is applied and baked it. Our Steel Shelving provides lasting durability with an outstanding appearance.

Advantages

- Open shelf units use sway bracing.

- Closed shelf units use backs and sides.

- A wide range shelving sizes.

- Standard color is dark gray, also available in other colors, mist gray, dove grey, sand, blue, tan, putty, red, black and pearl white.

- Light weight and easy to assemble.

- Powder coat finish.

- Adjustable steel flange shelves.

- Boxer (box shelf) adjustable steel box shelves are available.

- All 4 corners are lapped and welded for additional strength.

- Shelving units are available in 18, 20, and 22 gauge steel.

- Upright posts sizes vary from 3ft high – 16ft high.

- Light duty warehouse shelving.

- Auto parts storage shelving systems.

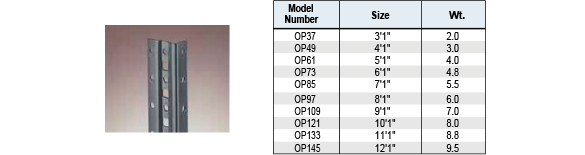

Shelving post

Offset Angle Post 1-1/2” O.C.

Made of 14 gauge cold-rolled steel, roll formed into a 1″x 1-7/8″ angle. The wide flange is punched on 1-1/2″ centers with 7/16″ square slots to receive shelf clips and 5/16″ diameter holes on 1-1/2″ centers for the atlach-ment of side sway braces or solid panels.

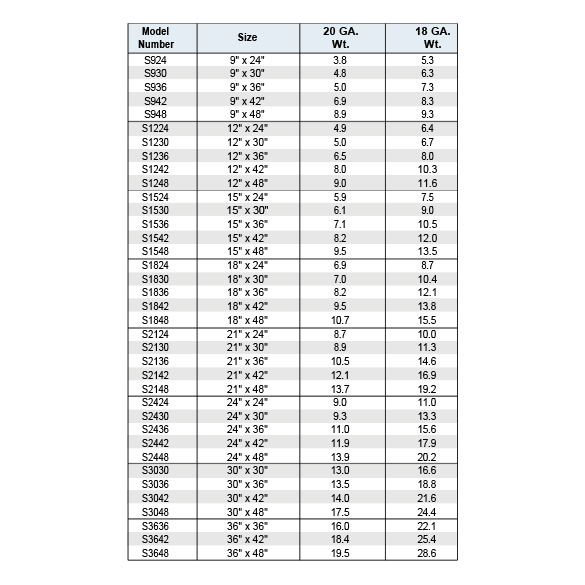

Flange & box shelves

Adjustable Steel Flange Shelves (For Clip-Type and Nut and Bolt)

All shelves are made of 20 or 18 gauge cold rolled steel.

Each side has triple bends for added strength.

NOTE: ADD SUFFIX X FOR 18 GAUGE

EXAMPLE: S924X = 18 GAUGE 9″ x 24″

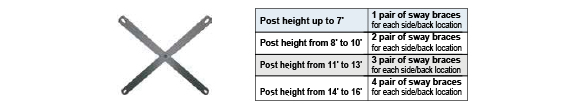

Sway braces, reinforcements, shelving clips & hardware

General Side/Back & Sway Brace Info

When supplying open shelving units, one pair of braces for each side/back location may not always be sufficient. The following is our recommended sway brace to unit height chart.

NOTE: Common sides and backs share sway bracing.

Angle sways & splices

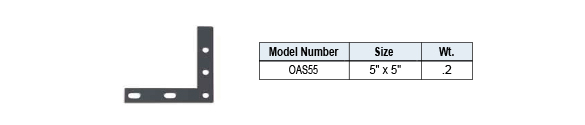

Offset Angle Sways (For 1-1/2″ on Center Shelving)

A 5″ x 5″ L-shaped bracket made of 11 gauge steel with one leg punched on 2″ centers and the other punched

1-1/2″ on center. Gives 5 points of fastening between shelf and upright to prevent lateral movement when sway bracing is not used.

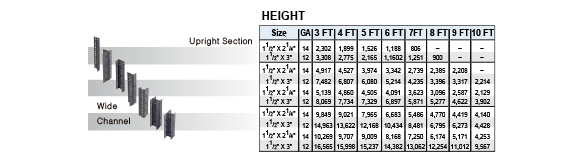

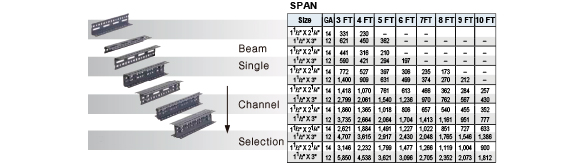

Slotted angle components & specifications

Load Capacities when Slotted Angle is used as Beams (Horizontal Members) in Pounds Each Section.

Combination sections are bolted together on 6″ centers. Capacities T-Section based on uniformly Loading

Direction Single Beam Single Beam Wide T-Section T-Section distributed load. For concentrated loads, use half these figures.

Load Capacities when Slotted Angle is used as Uprights (Vertical Posts) in Pounds Each Section.

To determine safe allowable load per column, use longest vertical space between horizontal braces.

NOTE: CAUTION: All loads given are based on uniform loading. Consideration must be given to concentrated loads, shock loads and methods using material handling.